Meet the Clay Masters of Tokoname in this mini-documentary on Bonsai ceramics!

Tokoname is one of the six famous old kilns of Japan, producing tea pots, sewer pipes and… Bonsai Pots. Though Tokoname was famous for its clay (Tokoname literally means "Always smooth"), much of that has ran out and what remains are highly skilled craftsman, with a reputation for quality Bonsai containers, both glazed and unglazed.

Invited by the Tokoname association, we shot this documentary on the true craftsmanship of the potters. Focusing on the process of creating a Bonsai pot, we filmed six artists in their ateliers.

The stars of the film:

Tatsuhiro Tanaka (Clay Atelier)

Katsushi Kataoka (Reiho, Seizan Toen)

Kazuhiro Watanabe (Ikko, Kanesho Seitosho)

Kakuyuki Watanabe (Kakuzan toen)

Katsuichi Shibata (Shibakatsu en)

Hidemi Kataoka (Shuuhou, Yoshimura toen)

And the process of creating Bonsai pots:

Step 1: Preparing the clay

At the Atelier of Tokoname clay they import, mix, purify and distribute all the clay for the all potters in Tokoname. For different types of pottery, there are different types of clay and the potters can customize their own mixture for the best characteristics.

Once the clay is at the potter, it will be kneaded by both hand and machine to enable the potter to work with it. Normally a potter uses a machine to make the clay more soft and then knead it in the right shape.

Next, there are three different ways to shape a pot. We'll explain the shaping with a mould first and after that describe how the wheel and manual methods work.

Step 2a: Shaping with a mould

The slab of clay is created by kneading the clay thoroughly and then creating thin layers by running a thin steel wire across the clay.

The slab is then rolled onto a pipe to transport it to the mould.

Finally, the slab is then pushed and shaped into the mould using a sand bag. Excess clay on the inside is now removed using a spatula, to make sure the thickness of the clay is uniform. The moulded pot then needs to dry for a day, before the mould can be removed. Usually this is the moment to add the stamp on the bottom of the pot, as well as creating holes for drainage. Finally, with some moulds the rim also needs to be added manually.

Step 2b: Shaping with a wheel

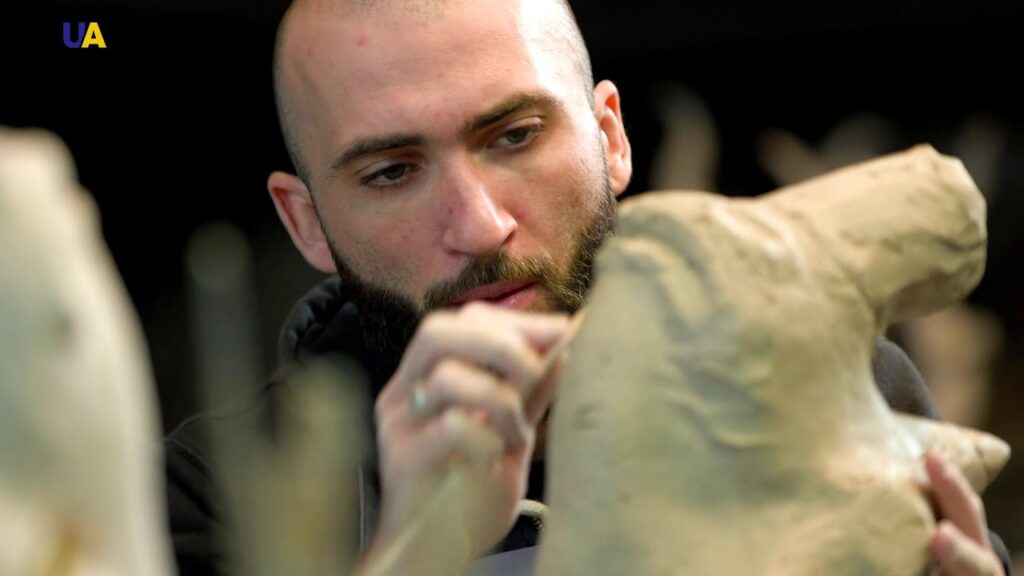

Using the wheel is probably the method that we always think of when talking about pottery. The potters show incredible craftsmanship when creating the perfect shape for the bonsai pot.

While the feet of the pot are automatically created when using a mould, the potter that uses the wheel as a shaping method, needs to create this separately (usually after one day of drying first).

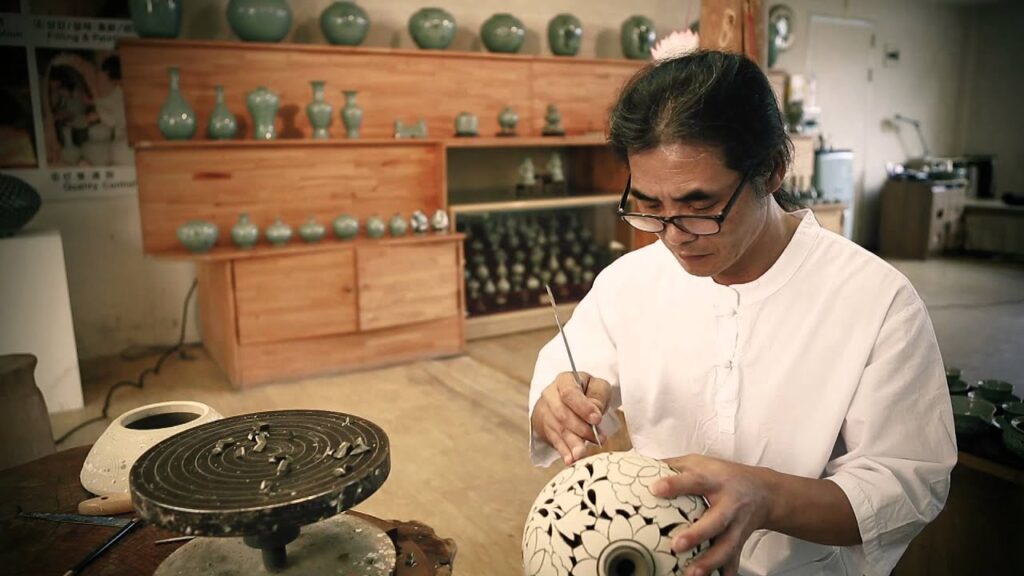

Step 2c: Shaping with clay slabs

Not all pots can be made using moulds or wheels. As not all can be similar in shape and not all are round. Some potters rather form the bonsai pots themselves using slabs that they cut out themselves. This enables them to make one of a kind pots that are exactly designed to their customer’s wishes. Usually the body of the pot is designed first and after a few hours drying the rim is added, and again a few hours later the feet can be created.

Step 3: Finishing and drying

Water finishing. To smoothen the surface and edges of the pot, the craftsmen use all kinds of cloths and cards that they dip in water.

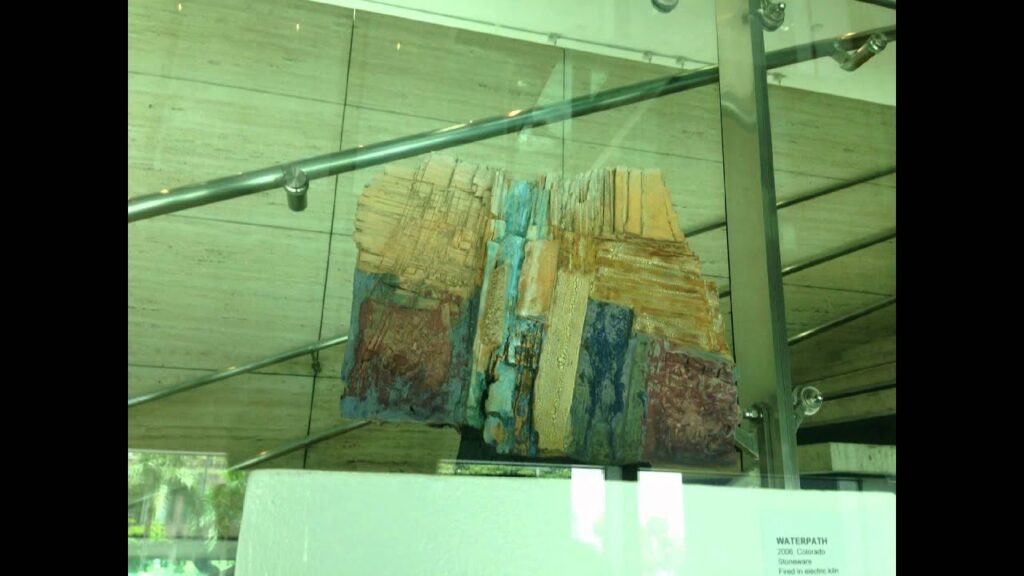

Drying. Drying makes sure that the pots stay in the right shape when being fired later. Drying can take between 1-3 days time depending on the size of the pot. On this photo several glazed pots are drying, almost ready to be fired.

Step 4: Glazing

Some pots are glazed, mostly to suit Deciduous or broadleaf evergreen trees. The pot is dipped into a basin of glaze, after which it is left to dry for about a day before being fired. Sometimes a second glazing is added and the pot would be fired again.

Step 5: Finishing and firing

Both the surface and the edges are polished and smoothened during the drying process, right before the firing.

After one day of drying the potter can add their own brand mark by either scribbling or pressing their name on the bottom of the pot.

The kiln is then packed with pots and over the course of about 30 hours heated to 1180 degrees Celsius, and cooled down again.

This film is a cooperation of Bonsai Empire with the Japan Patent Office (JPO) and the Japan External Trade Organization (JETRO).

Music, in order of playing: Chat roulette, Avert your Eyes, Water Lillies, 1.42, Still (Hiatus), Mana Two, Lullaby, Sixteen Twenty Five.

More information: